Do stainless steel weights need to be tested frequently?

2023-06-05

Do stainless steel weights need to be tested frequently?

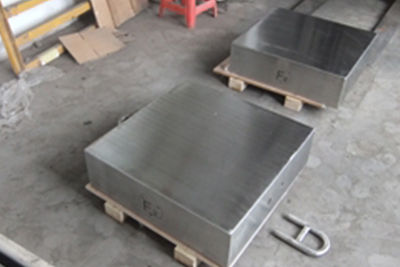

As a standard calibration instrument, weights need to meet the weight calibration regulations during production. In order to meet different usage needs, various specifications and grades of standard weights have been produced. The current standard weights used are mainly 316, 304, etc. High precision standard weights can be processed using 316 stainless steel, which is non magnetic. Therefore, 316 stainless steel can be used as E1 and E2 grade precision non magnetic standard weights, suitable for high-precision electronic balances. However, ordinary stainless steel has a relatively low nickel content, and its ability is relatively low, making it easy to be magnetized.

Rust steel weight

The stainless steel material determines the grade of standard weights. Before choosing, everyone needs to first clarify the occasion used. If it needs to be used in conjunction with high-precision electronic scales, it is necessary to choose higher grades of E1 and E2. If there are no requirements for accuracy, M1 grade standard weights can be chosen.

Operators using stainless steel weights will not pay too much attention to these, only designated personnel will pay attention, and after the accuracy level is updated, it is equivalent to the operating standards and regulations, and it needs to be updated at any time. Especially for some large production enterprises, it is even more necessary to update this accuracy level. Once the error exceeds the requirements, it will seriously affect the weighing effect. Even if the data is weighed, it cannot be used, which is time-consuming and labor-intensive. When the purchaser has doubts about the material or grade of stainless steel, they can go to the metrology department for inspection. They can inspect the specifications, grades, materials, and other contents of the standard weights. If the inspection results are qualified, they can be put into use normally. If the inspection is not qualified, they need to find an adjustment.

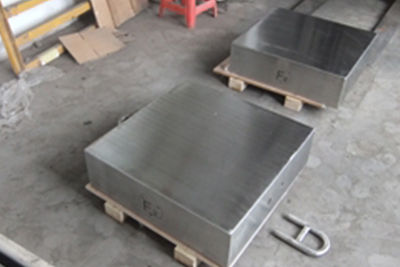

As a standard calibration instrument, weights need to meet the weight calibration regulations during production. In order to meet different usage needs, various specifications and grades of standard weights have been produced. The current standard weights used are mainly 316, 304, etc. High precision standard weights can be processed using 316 stainless steel, which is non magnetic. Therefore, 316 stainless steel can be used as E1 and E2 grade precision non magnetic standard weights, suitable for high-precision electronic balances. However, ordinary stainless steel has a relatively low nickel content, and its ability is relatively low, making it easy to be magnetized.

Rust steel weight

The stainless steel material determines the grade of standard weights. Before choosing, everyone needs to first clarify the occasion used. If it needs to be used in conjunction with high-precision electronic scales, it is necessary to choose higher grades of E1 and E2. If there are no requirements for accuracy, M1 grade standard weights can be chosen.

Operators using stainless steel weights will not pay too much attention to these, only designated personnel will pay attention, and after the accuracy level is updated, it is equivalent to the operating standards and regulations, and it needs to be updated at any time. Especially for some large production enterprises, it is even more necessary to update this accuracy level. Once the error exceeds the requirements, it will seriously affect the weighing effect. Even if the data is weighed, it cannot be used, which is time-consuming and labor-intensive. When the purchaser has doubts about the material or grade of stainless steel, they can go to the metrology department for inspection. They can inspect the specifications, grades, materials, and other contents of the standard weights. If the inspection results are qualified, they can be put into use normally. If the inspection is not qualified, they need to find an adjustment.

contact us

National Service Hotline

159-5359-3777

Website:http://e8d8ua9.2.magic2008.cn/

Email:sales@hmweight.com

Address:North of Fumin Road, Penglai City, Shandong Province Phone: